Our services

DESIGNING

Designing is the core of our activities. The specifics of opencast mining machines industry requires preparing an individual project taking into account the exploitation conditions and financial capability of the investor for each new venture. We do our best to combine our comprehensive knowledge and abilities with the investor’s requirements and experience in each project.

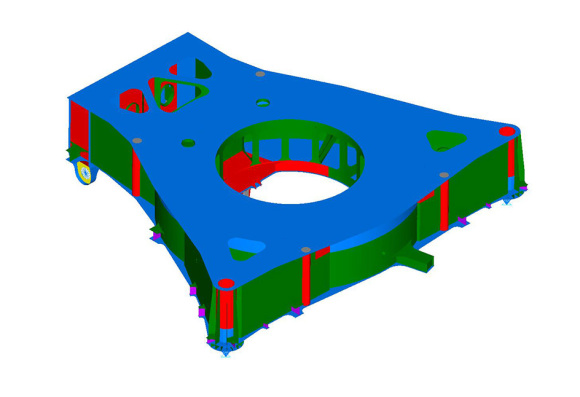

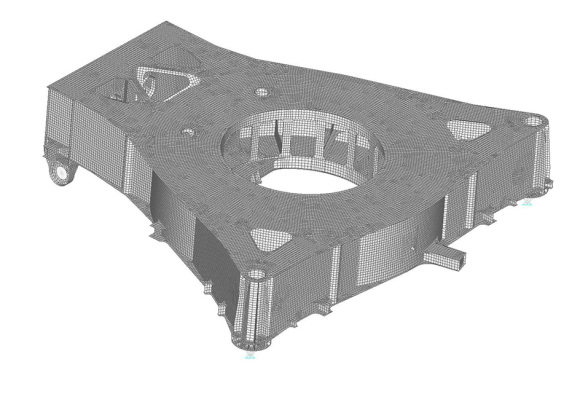

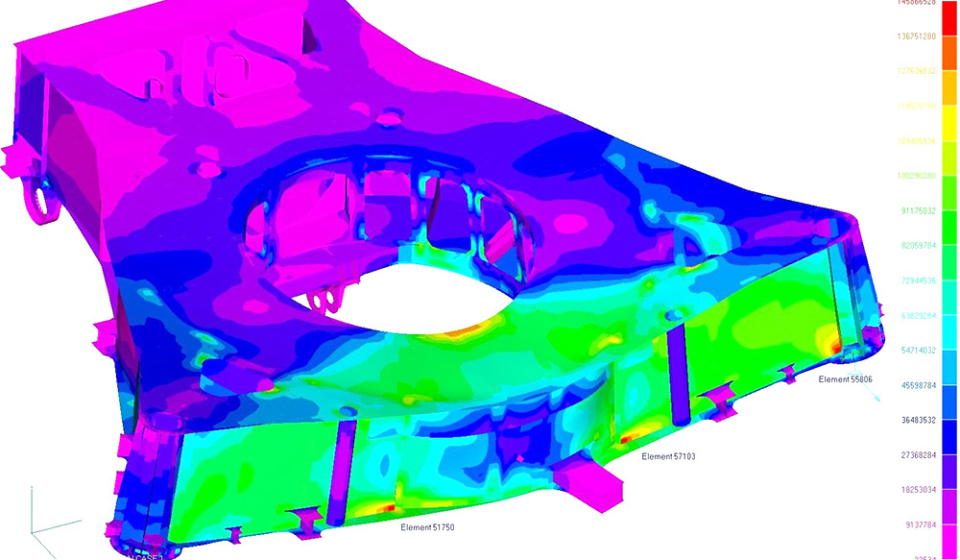

Implementing in the last few years challenging designing tasks (ZGOT-15400.120 dumping conveyor, KWK-910 excavator) our designing team worked with modern designing tools enabling comprehensive durability analyses as for the fatigue durability, stability, temporary durability with girder, surface and solid models, both linear and non-linear.

Designing machines for the exploitation of hard diggable deposits we have elaborated methods of modelling the bearing structure so as to minimize geometrical ridges, ensuring the required fatigue durability with rational expenditures for welded structures. We place great importance to dynamic reliability of the structure by carrying comprehensive dynamic analyses (modal and as a reaction of the body to dynamic forces) already at the initial designing stage.

Our competences

Advanced calculation processes

In our everyday designing work we try to take the most advantage of relatively simple designing tools. The designers can take advantage of Autodesk software: AutoCAD Mechanical, AutoCAD LT, Mechanical Desktop and Inventor and for calculations NE/Nastran as well as specialized software for calculating gilder structures elaborated in our company. The specification we prepare includes a whole design – from a detailed initial design for the evaluation of the offered solutions through the operational specification with the drawings of details up to the assembly specification.

The active participation of the designers in the implementation process and during the assembly of the objects triggers the constant improvement of construction solutions as for technological aspects and rationalization of the implementation costs.